our story

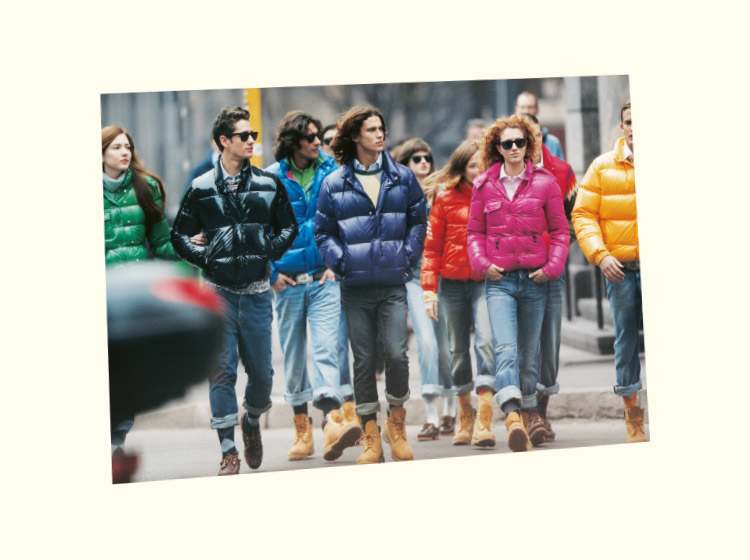

At the heart of Timberland’s story is a community – several communities – stepping outside to work hard together and move the world forward. With grit and a relentless dedication to problem solving, these bold doers embrace the adventures on their path.

our roots

DEFINED BY THE OUTDOORS:

Without New England’s fierce and demanding environs, there would be no Timberland. We started by equipping workers to power through the toughest outdoor environments.

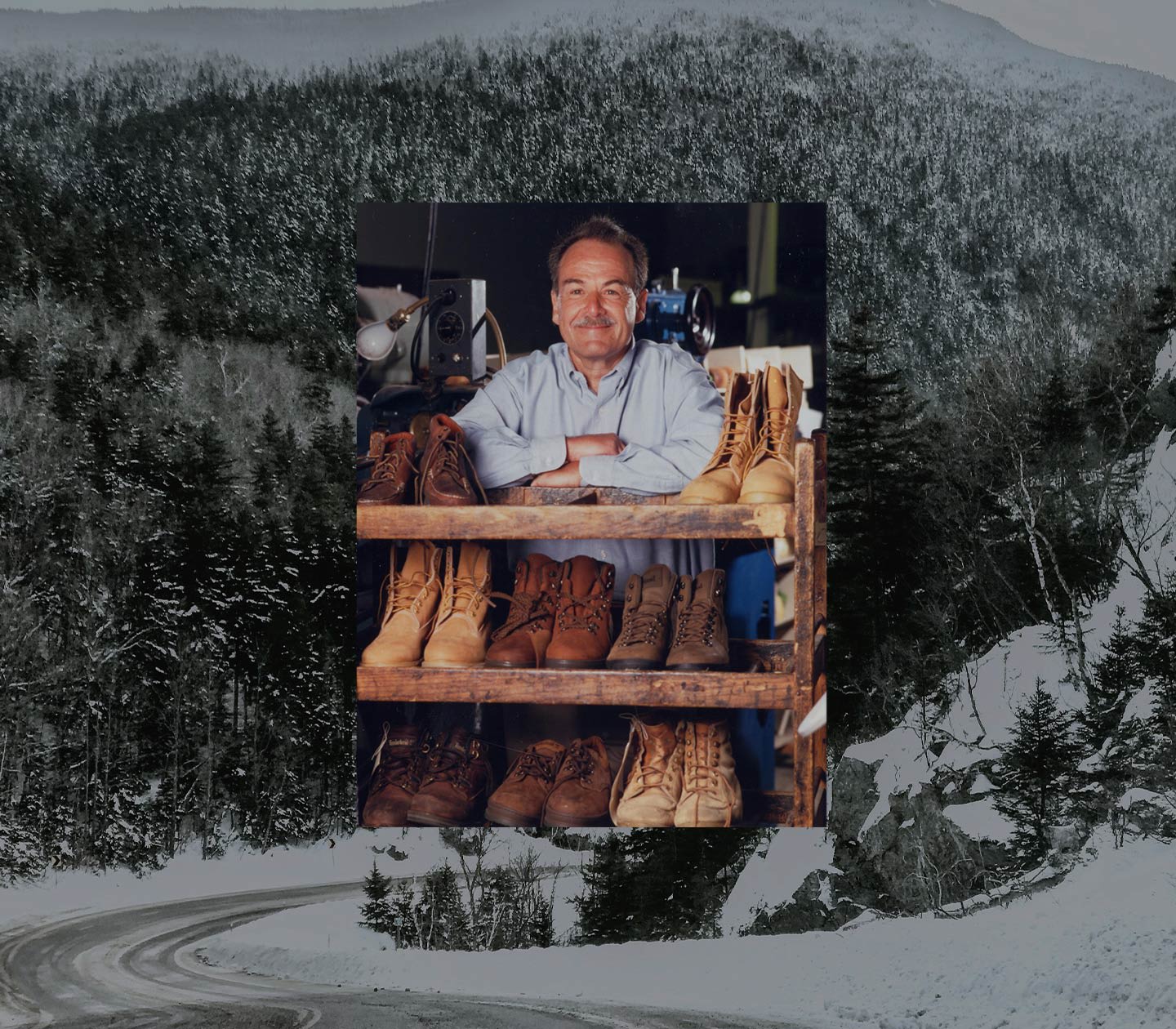

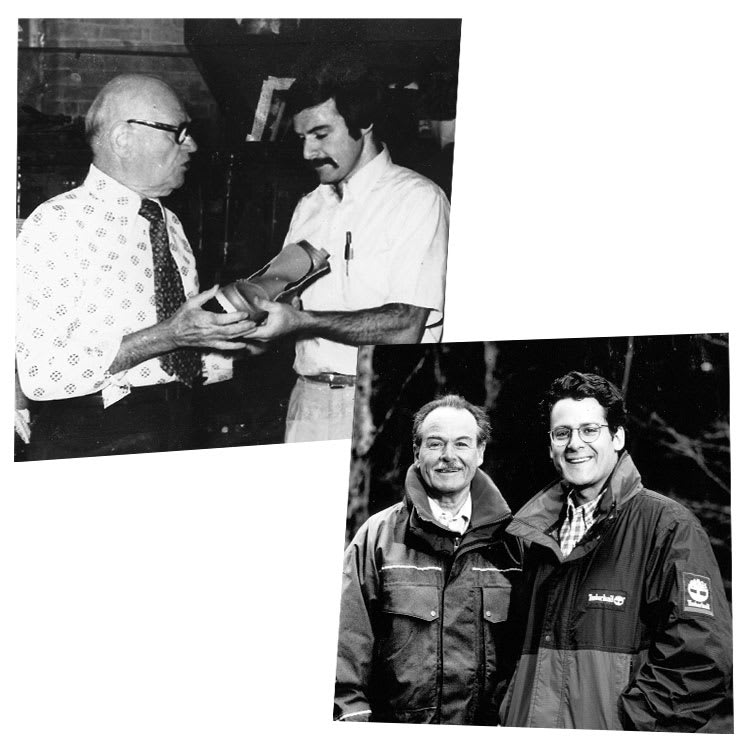

THE FOUNDING FAMILY

Born from the craftsmanship of our founder Nathan Swartz, who first developed waterproof boots with his son Sidney, who then went on to brand the boots. Sidney’s son Jeff took the company on a journey of purpose that drive the values today.

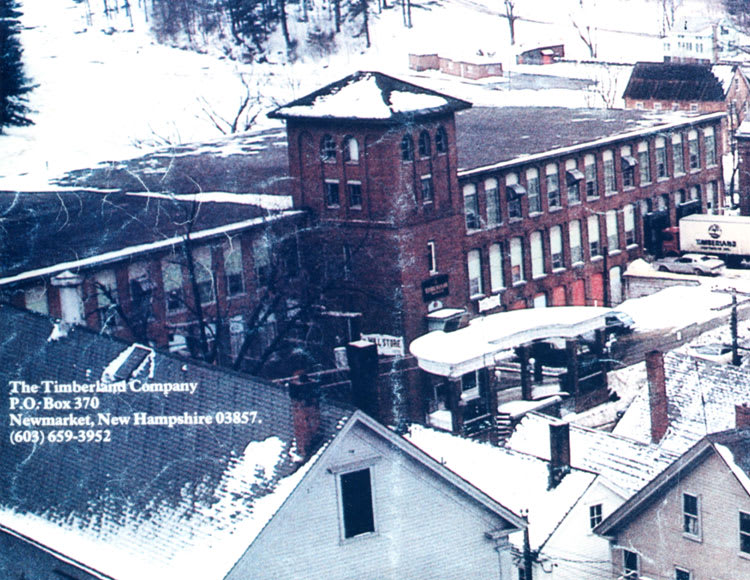

THE ORIGINAL FACTORY

In 1955, Nathan took full control of Boston-based Abington Shoe Company and moved operations to a damp and drafty riverside factory in a quiet New England town in the U.S.

THE ORIGINAL

TIMBERLAND® BOOT

The yellow boot that started it all. In 1973, an icon was born when the Abington Shoe Company launched the Original Timberland® 8-inch Boot. The 6-inch version was released three years later, becoming the icon we know today.

TIMBERLAND TODAY

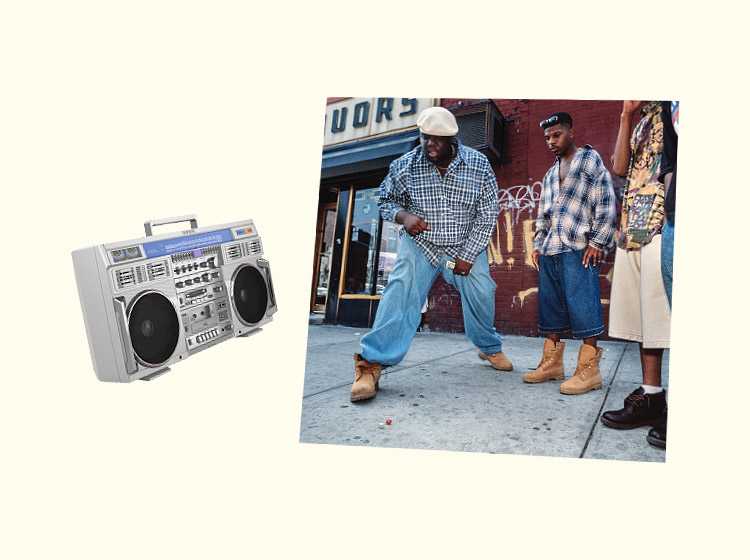

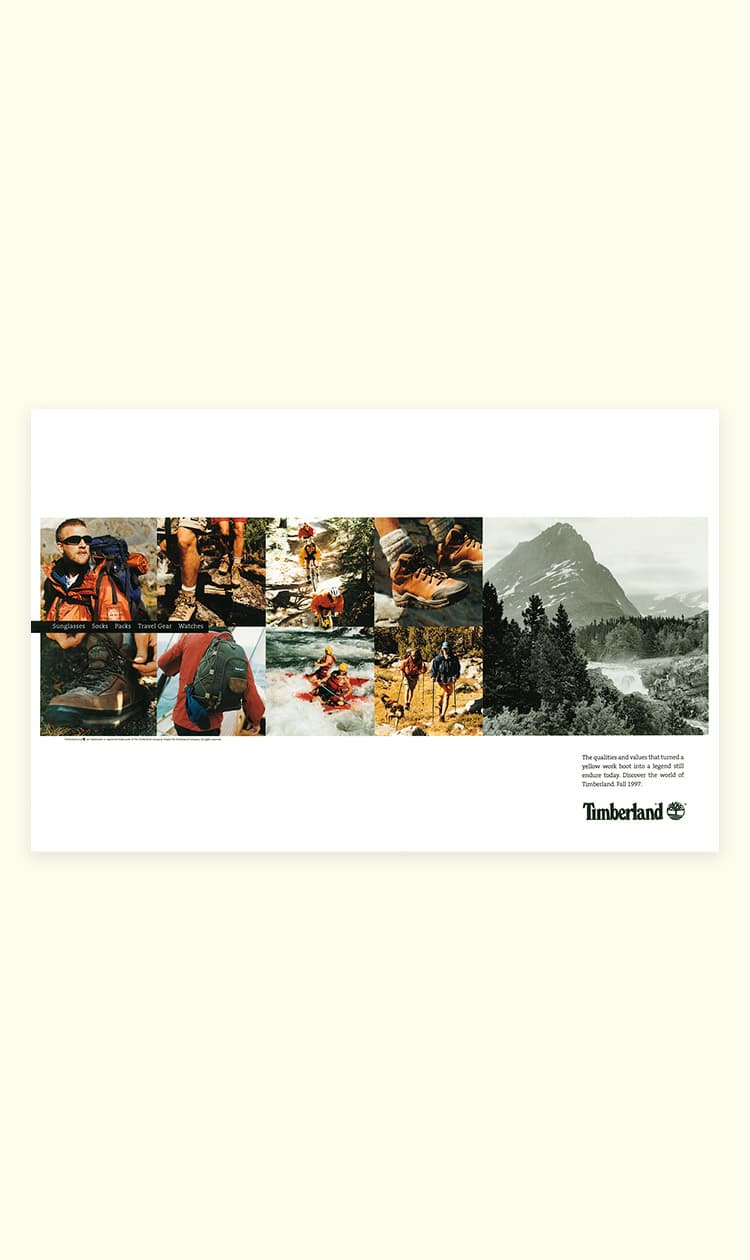

Today we are one global brand with three distinct categories: Work, Life and Outdoor. They encompass all our products, whether on the job, trail, street or stage.

CULTURE OF

INNOVATION

Ever since the day we created our first yellow boot, we’ve been inspired by that gritty New England tendency to ‘think outside the box’ and create innovative solutions to everyday problems.

icons

The original timberland®boot / 3-EYE Lug HANDSEWN

BOAT SHOE / EURO HIKER /

The original timberland®

boot /

our vision

From the start, we used our products to solve problems. This dedication grew to solving problems for our communities. That dedication has stayed constant and grown into tackling bigger issues like climate injustice and responsible manufacturing.

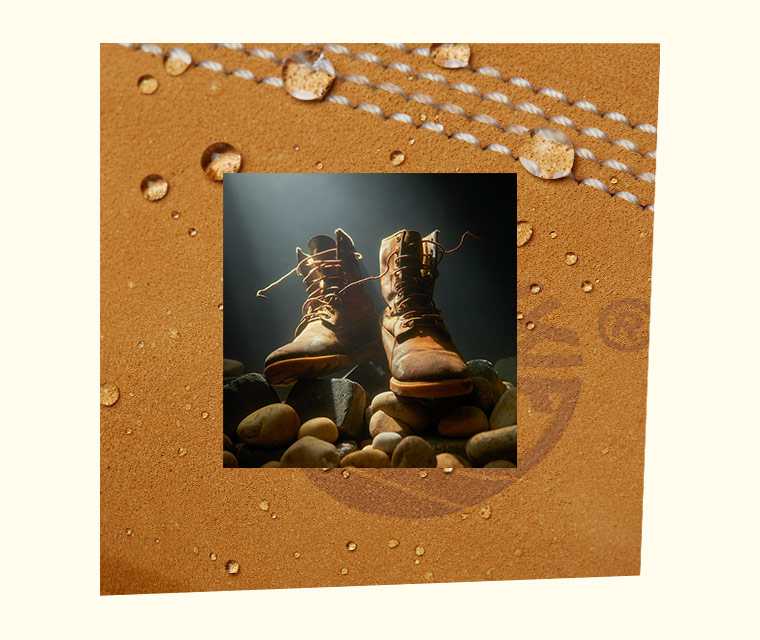

A factory worker had the clever idea of slathering silicone on his leather boots to keep his feet dry. This inspired our founders to use injection molding to make the leather boots fully waterproof. As the ultimate test, they sunk the boots with rocks in a factory toilet.

The introduction of injection molding technology seamlessly bonded the soles with the uppers. This created some of the first truly waterproof leather work boots, which were comfortable and lightweight to wear, revolutionizing the footwear industry.

A factory worker had the clever idea of slathering silicone on his leather boots to keep his feet dry. This inspired our founders to use injection molding to make the leather boots fully waterproof. As the ultimate test, they sunk the boots with rocks in a factory toilet.

The introduction of injection molding technology seamlessly bonded the soles with the uppers. This created some of the first truly waterproof leather work boots, which were comfortable and lightweight to wear, revolutionizing the footwear industry.

Problem solvers since the beginning, we introduced our Timberland PRO® range delivering comfort and performance to skilled workers and later the Earthkeeper® boots, made with recycled materials. Today, we continue to innovate by incorporating recycled, renewable, and regenerative materials in our products.

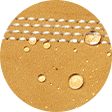

Waterproof

technology

Providing standing comfort, shock absorption & energy return all day.

Delivering premium comfort with a sole made from at least 65% renewable materials.

Our regenerative leather, rubber and cotton uses a technique that gives land a rest so it can absorb carbon, retain water and restore biodiversity.

Problem solvers since the beginning, we introduced our Timberland PRO® range delivering comfort and performance to skilled workers and later the Earthkeeper® boots, made with recycled materials. Today, we continue to innovate by incorporating recycled, renewable, and regenerative materials in our products.

Waterproof

technology

Providing standing comfort, shock absorption & energy return all day.

Delivering premium comfort with a sole made from at least 65% renewable materials.

Our regenerative leather, rubber and cotton uses a technique that gives land a rest so it can absorb carbon, retain water and restore biodiversity.

Our TimberloopTM Circular Design Platform aims to limit waste at each stage of the product life cycle, from how products are made to how used products can find a second life.

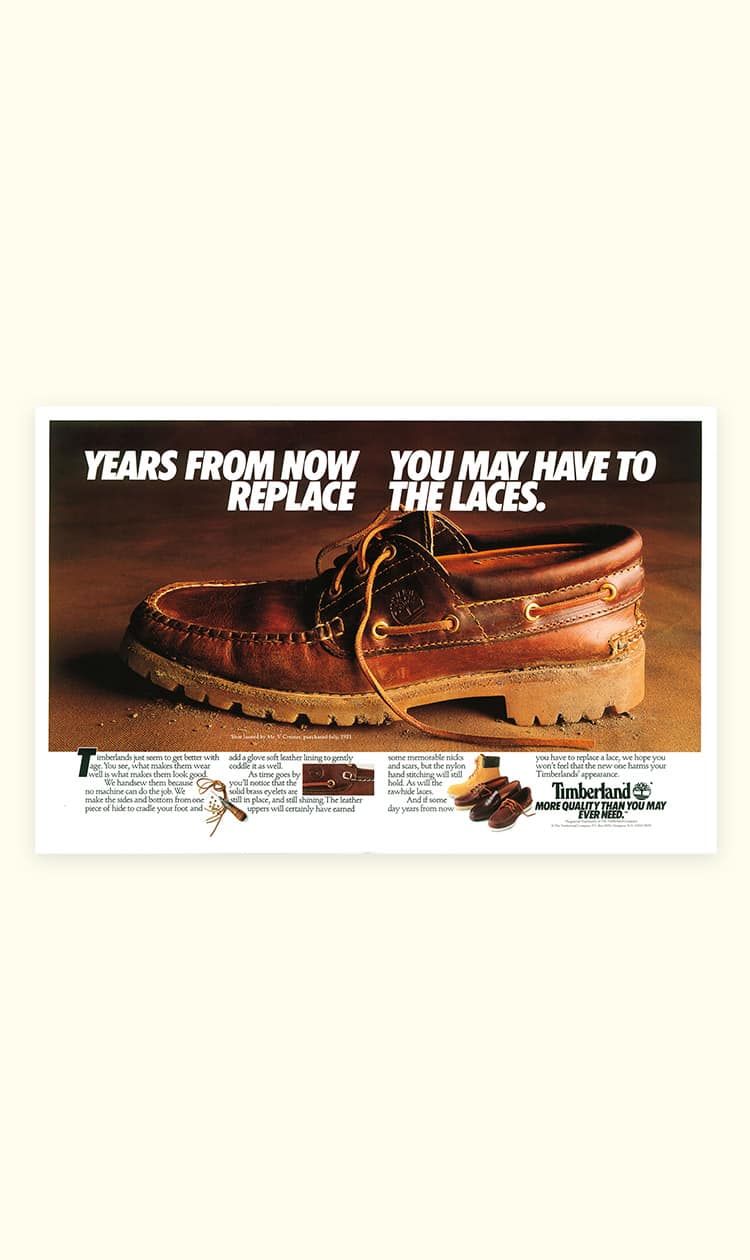

We’ve produced high quality, durable products for over 50 years, believing longevity is a greatest form of sustainability.

For a product to last a long time, it must be well cared for with the right balms, cleaners and brushes.

When your product reaches the end of its life, don’t throw it out, return it to our select stores.

Check out our Timberloop™ Collection designed to be returned through our take back program at the end of its useful life.

We’ve produced high quality, durable products for over 50 years, believing longevity is a greatest form of sustainability.

For a product to last a long time, it must be well cared for with the right balms, cleaners and brushes.

When your product reaches the end of its life, don’t throw it out, return it to our select stores.

Check out our Timberloop™ Collection designed to be returned through our take back program at the end of its useful life.

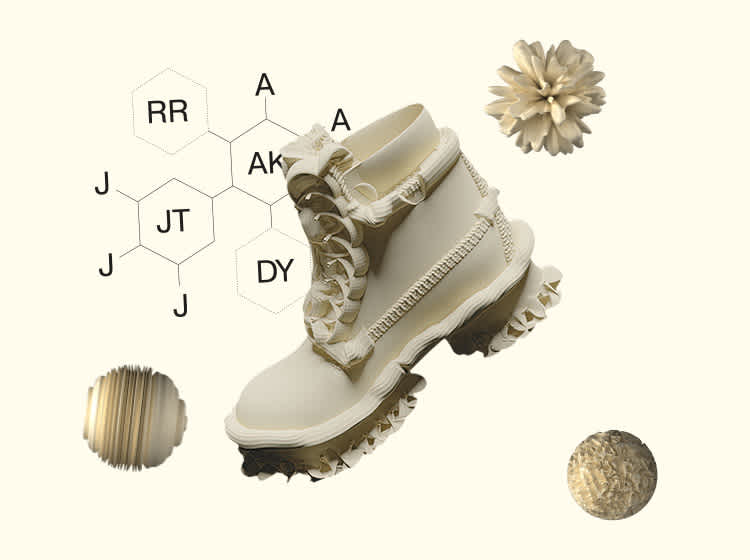

A workshop where a team of innovators & creators rethink every step of the boot making process, to define what the future of Timberland® boots can be, pushing the boundaries of design and innovation.

Located less than five miles away from the original factory, The Shed in Timberland’s US HQ in New Hampshire is Timberland’s own maker space dedicated to testing and developing new footwear and apparel ranges.

A workshop where a team of innovators & creators rethink every step of the boot making process, to define what the future of Timberland® boots can be, pushing the boundaries of design and innovation.

Located less than five miles away from the original factory, The Shed in Timberland’s US HQ in New Hampshire is Timberland’s own maker space dedicated to testing and developing new footwear and apparel ranges.

The original timberland®

boot

Our namesake since 1973 – a rugged waterproof work boot. Silicone-injected premium leather. Four-row stitching. Iconic wheat colorway. Still our signature after 50 years.

The original timberland®

boot

WATERPROOF

WATERPROOF

THE “TREE” LOGO

THE “TREE” LOGO

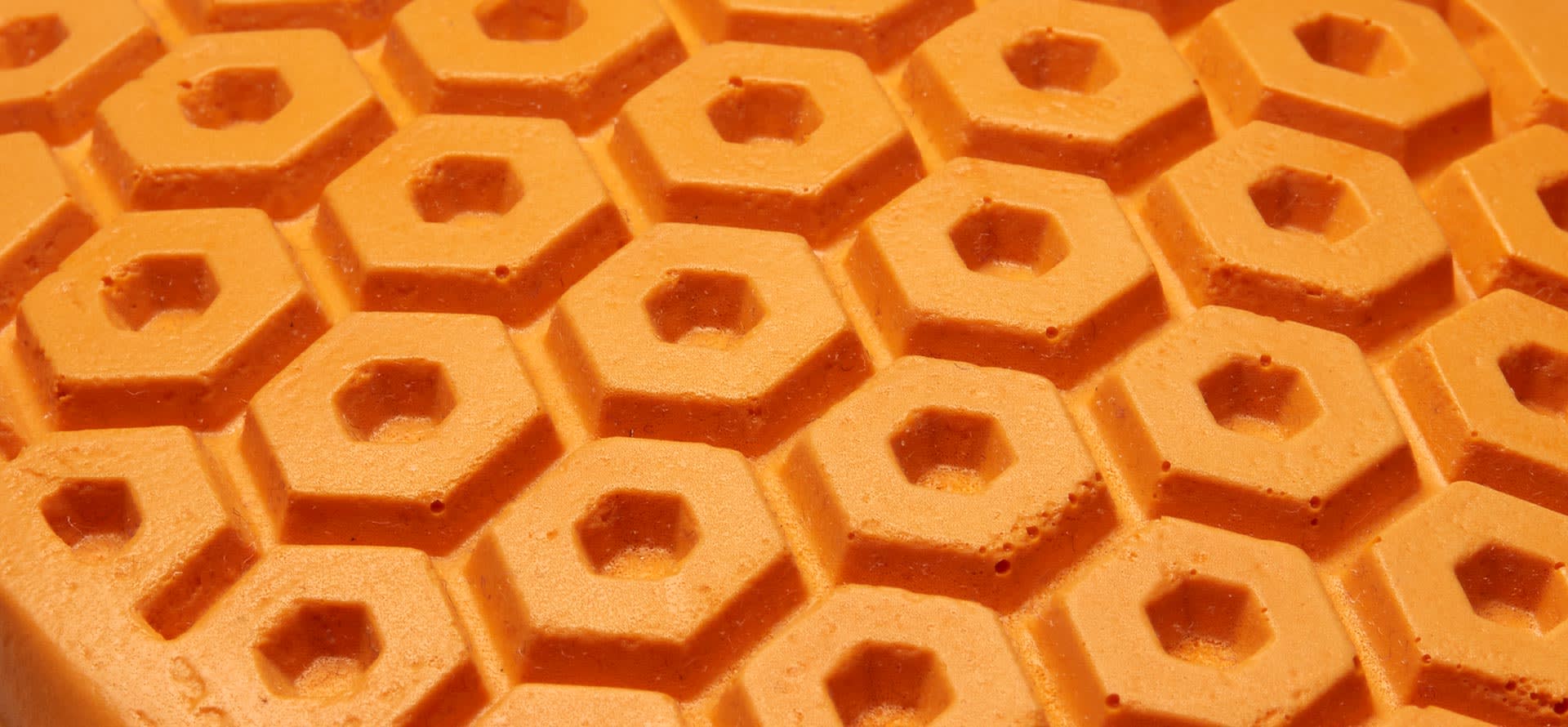

HONEY LUG SOLE

HONEY LUG SOLE

anti-fatigue

technology

anti-fatigue

technology

primaloft®

eco insulation

primaloft®

eco insulation

leather linings &

padding

leather linings &

padding

four rows of

stitching

four rows of

stitching

solid brass

eyelets

solid brass

eyelets

3-EYE LUG HANDSEWN BOAT SHOE

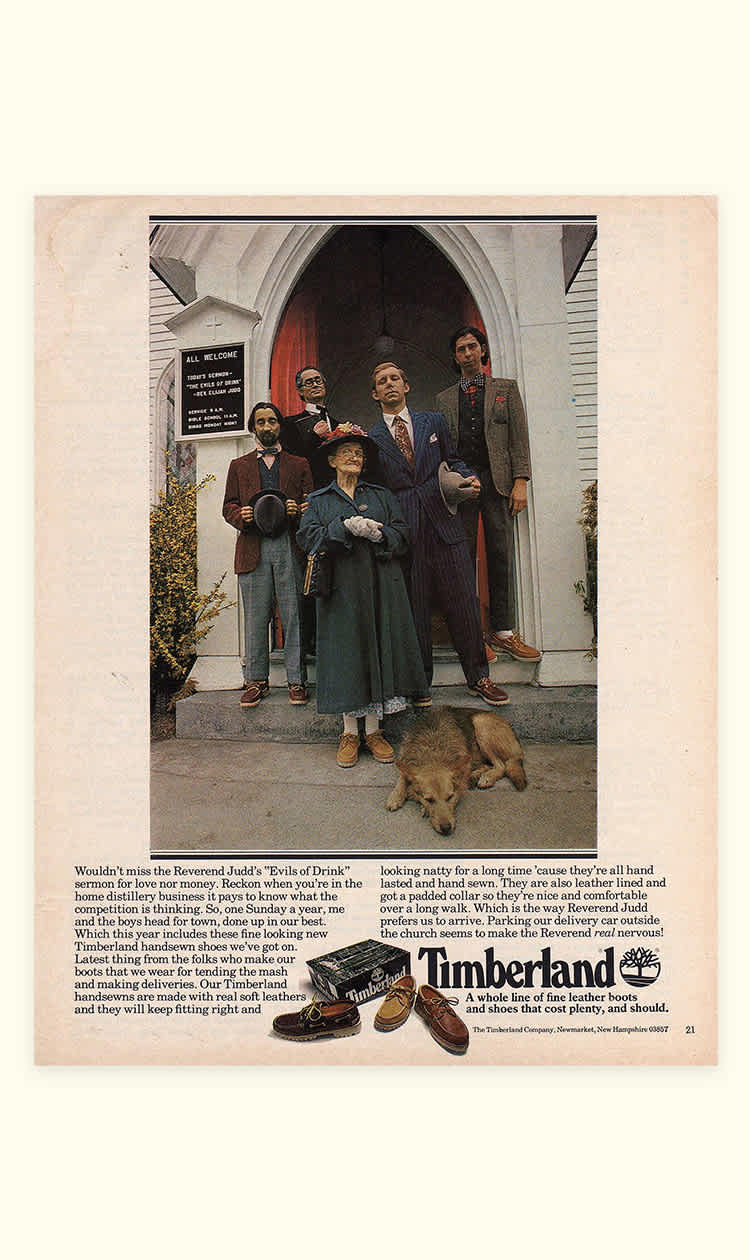

In 1978, we produced a durable summer shoe for adventurous vacationers everywhere by hand stitching a premium leather moccasin upper, and attaching it to our rugged boot lug outsole.

EURO

HIKER

The hiking shoe reimagined with a lightweight sole that brought sneaker-like comfort to the trail. Some say this mighty shoe helped ‘day hiking’ take off across the globe and gave new freedom to outdoors lovers everywhere.

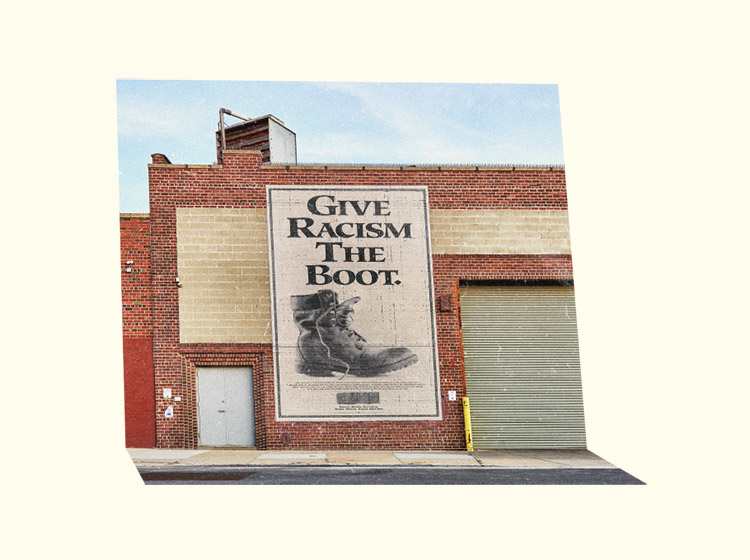

From the start, we used our products to solve problems. This dedication grew to solving problems for our communities. That dedication has stayed constant and grown into tackling bigger issues like climate injustice and responsible manufacturing.

Timberland has a vision for a more equitable future. We are committed to strengthening communities through design education, volunteerism, urban greening and helping to close the skills gap in the professional trades.

We have always believed a greener future is a better future. In 1997, we celebrated the first Earth Day. In 2010, we co-founded the Climate Action Corps. We have been strengthening communities through urban greening. Plus, our Path of ServiceTM program gives all employees 40 hours of paid time to volunteer.